-

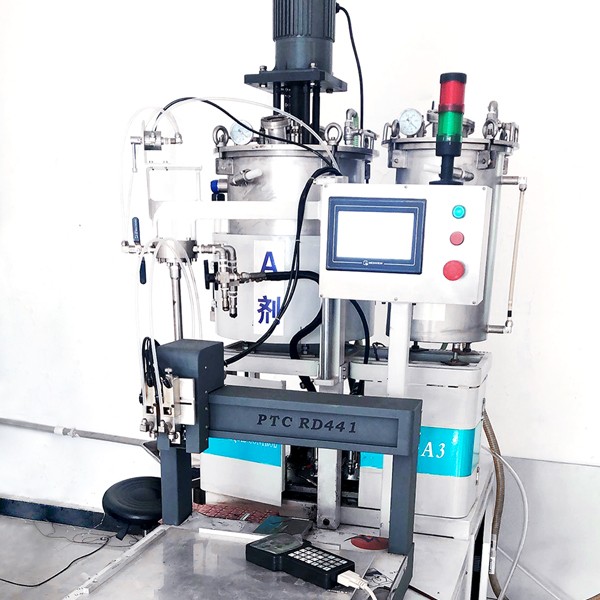

The automatic feeder will feed the product into the glue filling machine, vacuum the air, and inject the epoxy glue into the shell according to the preset parameters. Precise potting amount and has no bubble. Fully automated operation effectively solves the problem of low labor efficiency and improves the quality of production to a great extent.

Details -

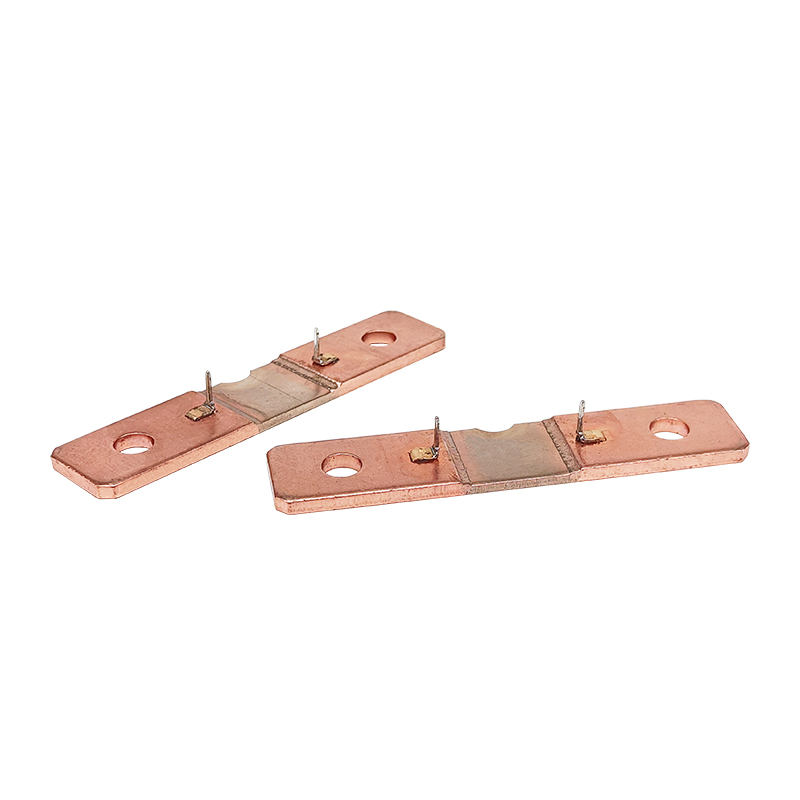

The automatic feeder will feed the workpiece into the equipment, the automatic resistance adjustment equipment will detect whether the workpiece resistance value conforms to the set resistance value range and fine-tune the resistance value of the products that do not conform to the set value.

Details -

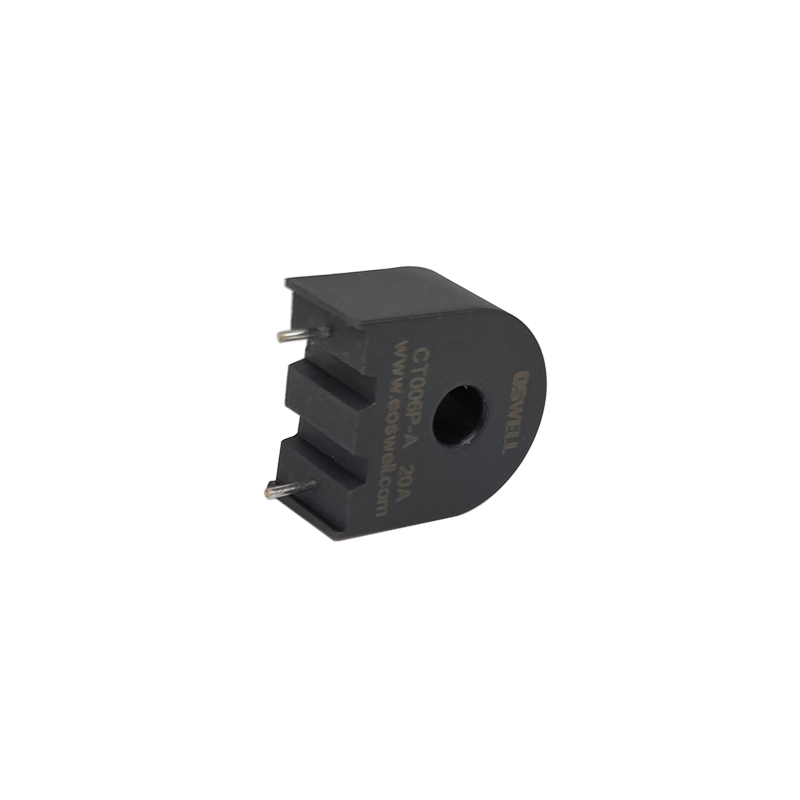

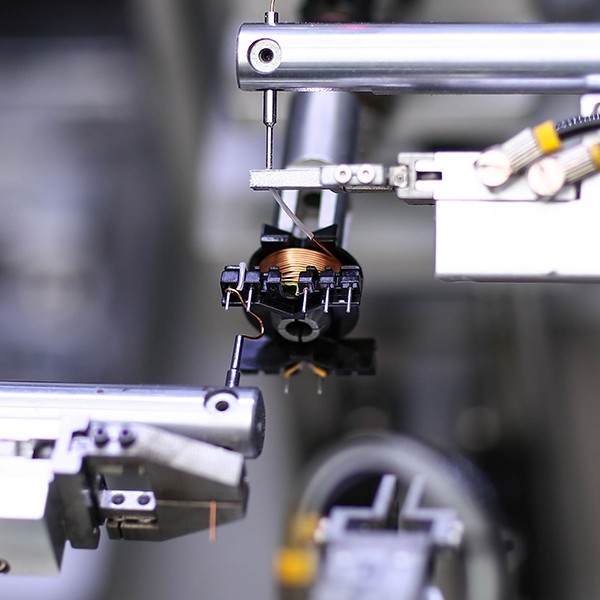

A number of bobbin are automatically loaded into the winding spool and start the winding machine to wind. The winding is stopped when the set number of winding is reached. That will have good uniformity and consistency of winding.

Details -

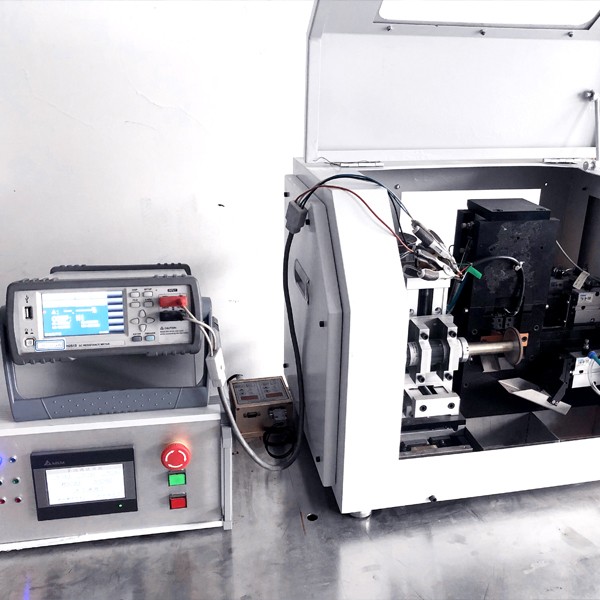

E-B welding technology can weld refractory alloy and refractory materials, no electrode, not easy to oxidize, good weld performance, small welding deformation, high welding precision and high productivity.

Details

-

23-08-2025

The 1P&3P Meter Terminal Block is a precision-engineered electrical component designed for secure and efficient connections in energy metering systems. "1P" refers to single-phase metering, while "3P" indicates three-phase metering compatibility. This terminal block serves as a critical interface between electrical meters (e.g., kWh meters) and power distribution circuits, ensuring accurate data transmission and system safety. Its compact, modular design simplifies wiring in residential, commercial, and industrial electrical panels while adhering to global standards for reliability and performance.

-

28-08-2025

Shenzhen, China – August 23, 2025 – GELAN Electric, a leading innovator in electrical components, today announced the global launch of its 1P&3P Meter Terminal Block, designed to address the growing demand for reliable and scalable energy metering solutions in smart grids and renewable energy systems.

-

23-08-2025

TCL CSOT has achieved a critical milestone with the mass production launch of its P1.2-pitch COB Mini-LED displays at its Suzhou manufacturing base. The product, featuring adjustable brightness (0-800 nits) and a 5,000:1 contrast ratio, was completed 15 days ahead of schedule, signaling TCL’s aggressive entry into the competitive LED direct-view market.