-

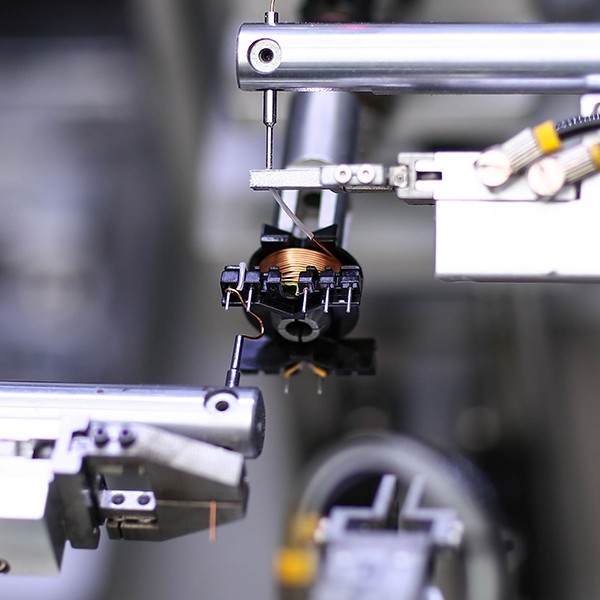

Automatic Winding Process

A number of bobbin are automatically loaded into the winding spool and start the winding machine to wind. The winding is stopped when the set number of winding is reached. That will have good uniformity and consistency of winding.

Details -

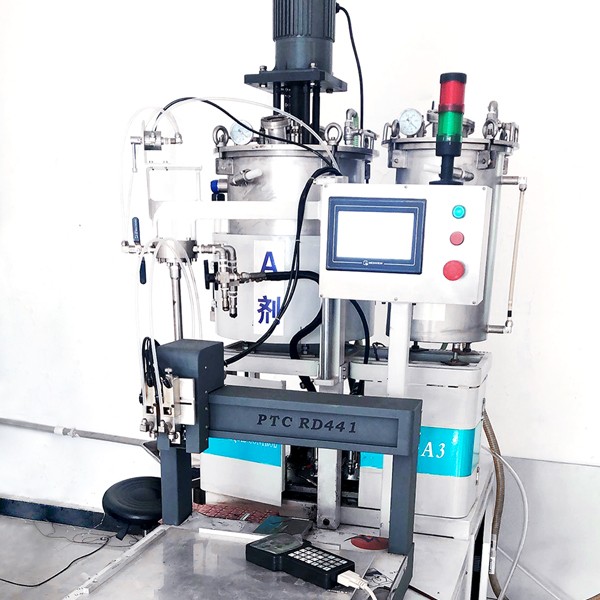

Automatic Potting Process

The automatic feeder will feed the product into the glue filling machine, vacuum the air, and inject the epoxy glue into the shell according to the preset parameters. Precise potting amount and has no bubble. Fully automated operation effectively solves the problem of low labor efficiency and improves the quality of production to a great extent.

Details -

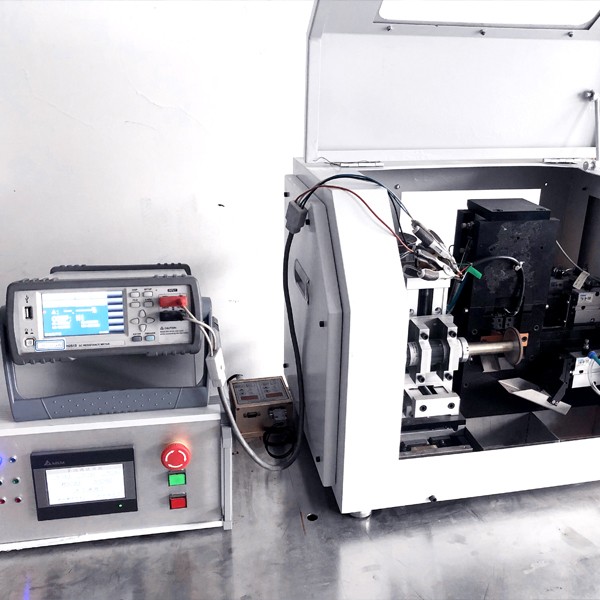

Automatic Resistance Adjusting Process

The automatic feeder will feed the workpiece into the equipment, the automatic resistance adjustment equipment will detect whether the workpiece resistance value conforms to the set resistance value range and fine-tune the resistance value of the products that do not conform to the set value.

Details -

High Temperature E-B Welding Process

E-B welding technology can weld refractory alloy and refractory materials, no electrode, not easy to oxidize, good weld performance, small welding deformation, high welding precision and high productivity.

Details -

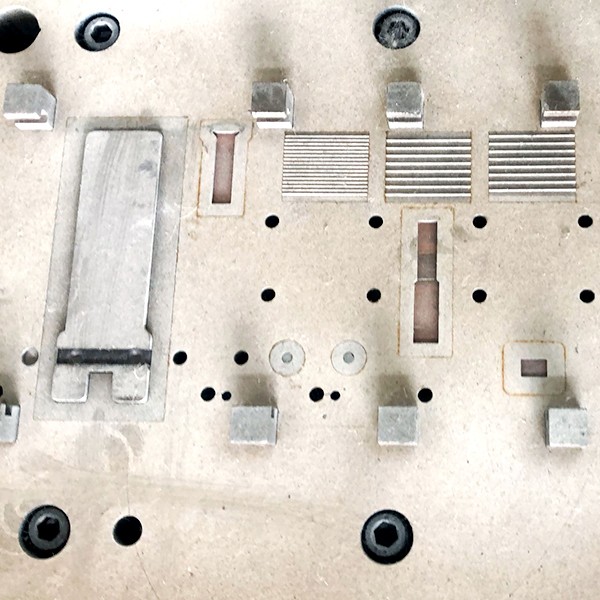

Automatic Stamping Process

Use strip stamping raw material in the stamping stroke. Several different stations are used on the mold to complete the cold stamping die of multiple stamping processes at the same time. The die is stamped once, and the material belt is moved once, until the product is finished.

Details