The automotive and aerospace sectors demand relays that combine mechanical reliability with solid-state precision. Hybrid latching relays now integrate magnetic latching mechanisms with solid-state switches, offering the benefits of zero contact wear (from solid-state components) and fail-safe latching (from traditional designs).

As 5G networks and IoT ecosystems expand, latching relays are evolving to meet stringent speed and signal integrity demands. Engineers now leverage micro-electromechanical systems (MEMS) and GaN-based drivers to achieve switching speeds under 1 millisecond—10x faster than traditional relays.

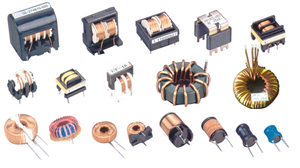

The latest advancements in latching relay technology focus on enhancing energy efficiency and durability through innovative magnetic core materials. Traditional relays rely on ferrite or alnico cores, but modern designs now integrate advanced composite materials like nanocrystalline alloys or amorphous metals.

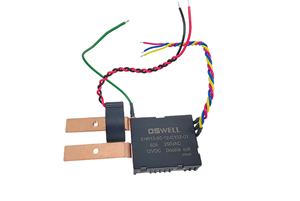

Decoding the Comprehensive Structure of the 100A Magnetic Latching Relay with Shunt Technology

The intricate design of the 100A Magnetic Latching Relay equipped with shunt technology is a testament to its engineering prowess. At its core, the product is composed of several essential components that harmoniously work together to deliver exceptional performance.

The 100A Magnetic Latching Relay distinguished by its shunt feature possesses a unique set of attributes that set it apart in the electronics landscape. Firstly, its robust design allows it to handle massive current capacities, making it ideal for demanding applications where reliability and durability are paramount.

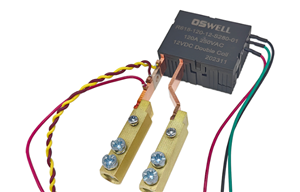

The 100A Magnetic Latching Relay equipped with a shunt mechanism stands as a versatile component in the realm of industrial automation and control systems. This advanced relay offers high current handling capabilities, enabling it to find significance in numerous industries.

Magnetic latching relays (MLRs) integrated with current transformers (CTs) are emerging as powerful tools in modern electrical engineering. These devices combine the advantages of MLRs' unique latching mechanism with CTs' ability to measure high currents accurately.

The 100A Magnetic Latching Relay with shunt has diverse application fields due to its outstanding features and capabilities.

Latching relays are commonly used in industrial automation systems due to their ability to maintain their position without continuous power supply. However, like any other electrical component, latching relays can experience faults and require regular maintenance to ensure optimal performance. In this article, we will discuss the common issues associated with latching relays and the appropriate troubleshooting and maintenance procedures.

Latching relays, also known as impulse relays, are widely used in industrial automation due to their unique characteristics and capabilities. These relays are commonly employed in various applications within industrial automation systems, providing efficient and reliable control of electrical circuits. In this technical article, we will explore the applications of latching relays in industrial automation and the benefits they offer.