A measurement method for parallel resistance of solar cells

A measurement method for parallel resistance of solar cells

1. The larger the series resistance is, the more the short circuit current drops, and the more the filling factor will accordingly; The smaller the shunt resistance, the greater the current, the more the open circuit voltage drops, and the more the fill factor drops.

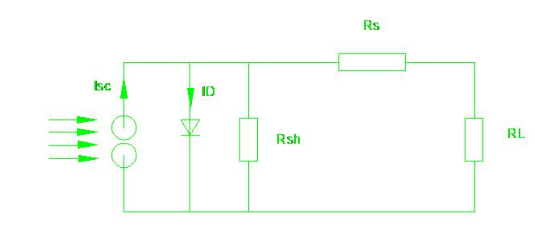

2 crystal silicon solar cells have series resistance and parallel resistance, the battery can be simply viewed as such a model: a constant current source in series a resistor, a resistor in parallel;

Series resistance: is generally caused by the resistance of the front silver grid, the resistance of the silicon material itself and the resistance of the aluminum back field.

Parallel resistor: Actually there is no such resistor, because the battery has a leakage current, it is the opposite direction of the battery output current! Therefore, part of the output current will be offset and the output current will be reduced, which is equivalent to a resistor connected in parallel to a battery.

3. Severe surface leakage increases and decreases in parallel

A large number of compound leakage and parallel in the emission region will not produce obvious changes

The essence of the parallel resistance is just an expression of the energy consumed by the battery itself

It's not necessarily accurate and please forgive me if there are any mistakes

4. Parallel resistance affected by the process: screen printing process health etching is not clean

5.Rsh is the side leakage resistance, that is, the parallel resistance, which is caused by the unclean edge of the silicon wafer and internal defects.

6. Small parallel resistance:

1\ First confirm whether it is the silicon wafer itself

2\ In terms of process: first check whether the sintering temperature is too high, resulting in burning through PN

Leakage breakdown PN

There is no etch through

The quality factor of the material itself is low

7. There are mainly 1. Junction area leakage - edge leakage, not engraved; Internal leakage, burning through, uneven diffusion, etc. 2. Leakage caused by the existence of crystal defects in the body, such as grain boundaries, metal impurities and other chip source. 3. Sediment formed by impurities in the piece, such as SiC, SiN, etc.

RS in the figure is series resistance, including body resistance, surface resistance, electrode resistance, contact resistance between electrode and silicon meter, etc

Rsh is the leakage resistance, that is, the parallel resistance, caused by the unclean edge of the silicon wafer and internal defects

RS is small, Rsh is large and ideally negligible, Ish is small

Series and parallel resistance has a great influence on the filling factor (FF). The higher the series resistance Rs, the more the filling current drops, the more the filling factor decreases, and the more the parallel resistance decreases, the same effect.