single-turn current transformer Core column type

Core column type: The primary coil is a copper column installed in the wall-penetrating magnetic sleeve, and the wall-penetrating

The magnetic sleeve is the main connection between the primary coil and the secondary coil and the primary coil to the ground.

Insulation, the iron core is made of silicon steel pieces bent into a spiral shape, which is

This can speed up the manufacturing process and reduce core losses.

Busbar type: when the rated current is greater than 1500 amperes, the primary coil system

It is not suitable for the thick stem, so the rated voltage is 10-20

kV, when the rated current is above 2000 amps, it is made into a busbar type

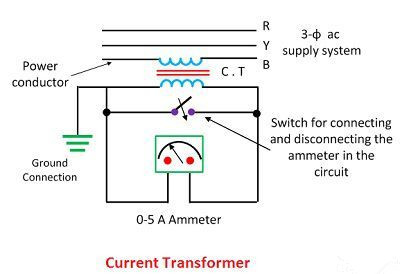

Transformer. The middle of this transformer is empty, and the primary coil is used to pass through

The current-carrying busbar of the transformer porcelain sleeve is replaced.

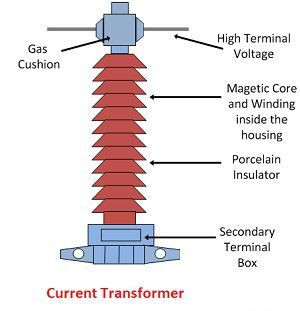

Bushing type: when the rated voltage is above 35kV, the bushing is widely used.

Tube type current transformer. The iron core is made into an annular shape, which is sleeved on the oil switch

On the insulating magnetic sleeve, use the current-carrying conductor in it as the original wire

lock up. The secondary coil is wound on the toroidal core. In recent years, more than 10 kV

Under the power distribution device, epoxy cast insulation is widely used

of the current transformer. Using this method of preparation can reduce its volume

Smaller, lower cost. Some core column transformers are made of casting type.