Surface temperature of shunt resistor

Resistors are made by using the properties of some materials that have a blocking effect on current flow. It is one of the most basic and commonly used electronic components. There are many uses of resistors in circuits, which can be roughly summarized as reducing voltage, distributing voltage, limiting current, and providing necessary working conditions (voltage or current) to various components. For convenience of expression, resistors are usually referred to as resistors for short.

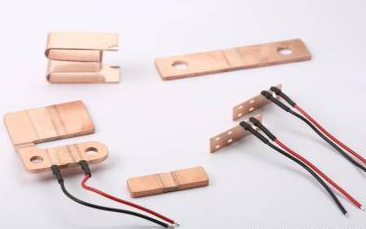

What is a shunt resistor? A shunt resistor is a resistor with a small resistance value for measuring DC current. It is made according to the principle of a voltage drop across the resistor when the DC current passes through the resistor, and converts the current signal into a voltage signal for DC current detection.

In the selection, you need to know two points: temperature drift and surface temperature.

In current sampling, current transformers are often used for the value of large AC current, while in the sampling of large DC current, a shunt, that is, a shunt resistor, is also called a shunt.

The principle of the shunt is to convert the current signal when the DC current passes through the resistor into the voltage detection signal generated at both ends of the resistor. Therefore, the shunt is required to have low resistance and high precision, can pass large current, and have excellent long-term stability.

While the shunt has high resistance value accuracy, it also needs to ensure good temperature drift performance. When the shunt is working, it is often sampled under a large current, so the surface temperature of the product is easy to increase due to self-heating, especially in the case of elevated ambient temperature and poor heat dissipation conditions. The increase of product temperature puts forward higher requirements for the temperature drift performance of alloy resistors. We often use the temperature coefficient of resistance (TCR) to measure the temperature drift performance of the product, the unit is ppm/℃, and the following formula is used to calculate:

TCR =

The smaller the temperature coefficient of resistance, the smaller the change in resistance value due to the increase in product surface temperature, and the smaller the difference in accuracy between operating at low current and high current.

According to the IEE standard, the recommended working current of the shunt should not exceed 2/3 of the rated current under normal working conditions, but the range of the measured current in practical applications is often larger, that is, the shunt can be required to be within 10%~100%. Work normally at rated current, even short-time overload needs to be considered. In view of the fact that shunts often work under high current and the operating current span is large, it is equally important to control the surface temperature of the shunt and control the temperature drift of the shunt, because the low temperature drift of the shunt is only meaningful if the surface temperature of the shunt is kept low. , in order to ensure that the resistance drift of the shunt is small when the current is sampled. When the surface temperature of the shunt is 30℃~70℃, its working state is the best, and its surface temperature cannot exceed 145℃ in any case, otherwise the resistance value of the resistance alloy will change irreversibly. It should be pointed out that, The surface temperature of the shunt should be measured from the center point of the resistance alloy.